Overview

Ensure your company develops robotic machinery that complies with all relevant regulations, standards, and directives with the support of expert guidance. Beyond meeting existing requirements, expert assistance is provided in areas where the rules are unclear or undefined. For situations with ambiguous or missing guidelines, practical solutions are offered based on extensive experience in functional safety.

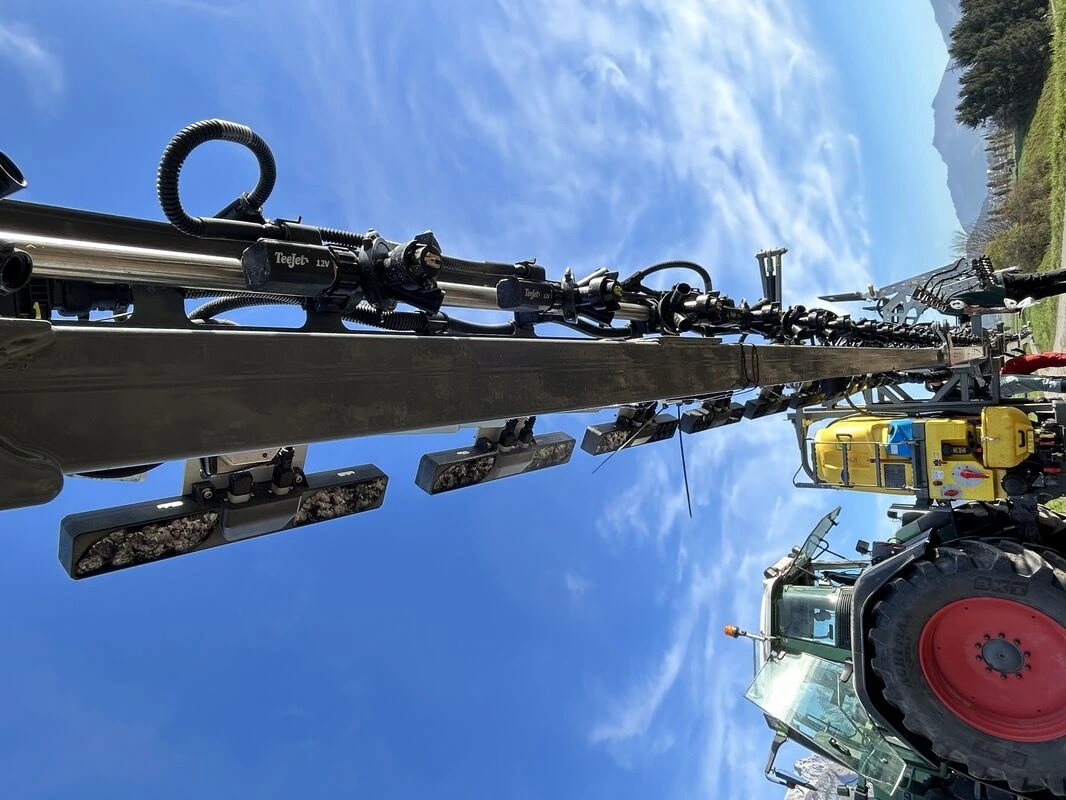

Autonomous robotic machinery often relies on complex sensor technologies, such as radar, LIDAR, and cameras, to detect nearby individuals. Demonstrating how these advanced sensors can be integrated into safety functions is challenging, as it involves considering not only traditional functional safety aspects but also emerging factors like AI and Safety of the Intended Functionality (SOTIF).

Support includes performing comprehensive risk assessments, identifying relevant safety functions, and establishing high-level safety requirements for each. Depending on the project's focus, further guidance can be provided to ensure the selected safety concept aligns with applicable functional safety standards.

More about the service

How can the service help you?

How the service will be delivered

Service customisation

- RISE - Research Institutes of Sweden | Website